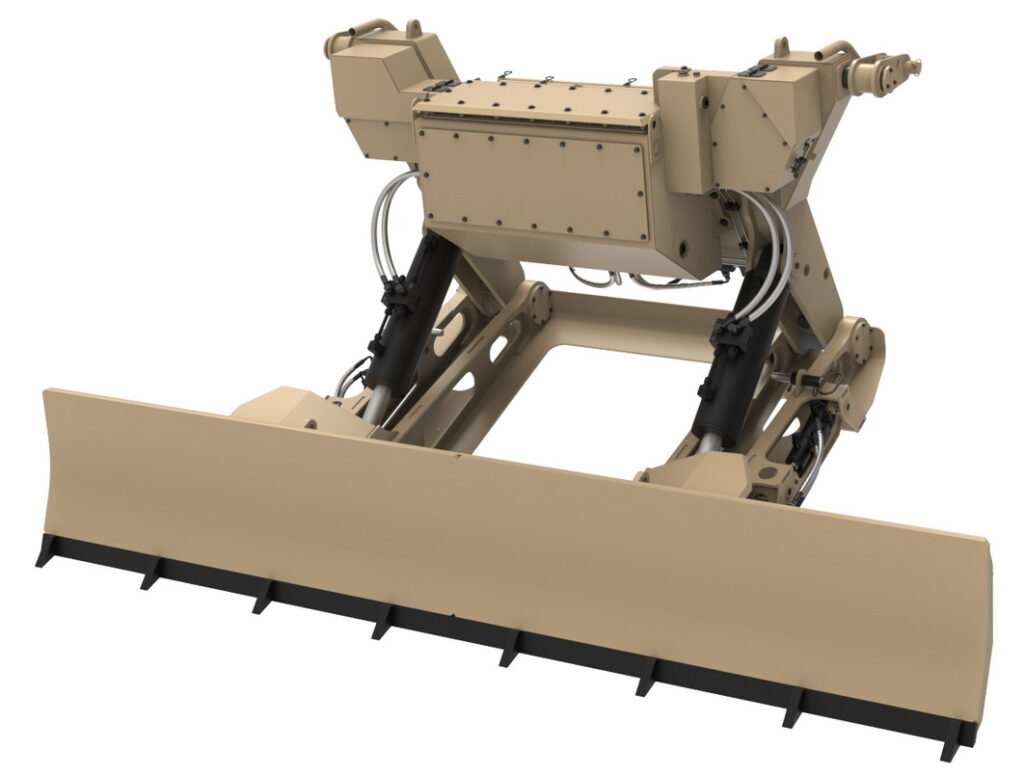

ADG Mobility (ADGM), a member of the OTT Group of companies, recently completed delivery and installation for a low-cost light engineering main battle tank (MBT) dozer blade system. All testing has been successfully completed to ensure compliance to the end-user’s requirements. The system is now in service in the Middle East attached to a main battle tank.

“Among the design considerations were a mass limitation of 1.2 tons and quick attachment and removal of the blade system in the field,” explained Andy Hodgson, Business Development Executive. “Another consideration was that no changes could be made to the ballistic, mine-blast or NBC (nuclear, biological, and chemical) integrity of the armour, with the crew fully buttoned up.”

Moreover, there was to be no electromagnetic interference, while the unit also had to be fully IP67 compliant for dust and water protection.

“The electro-hydraulic system is fully self-contained, including a motor cooling circuit to remove heat, as the system is required to operate for extended periods in ambient conditions up to 55° C,” he stated. “Another requirement was that the full operational functionality of all the turret systems could not be affected or degraded by the dozer operations, under any conditions.”

The light weight of the product makes it suitable for multiple tracked MBTs and wheeled 8×8 armoured vehicles. According to Hodgson, the unit can be installed or removed in the field by two crew members in less than five minutes.

ADGM offers straight (plain or teethed) replaceable blade segments, and is working on concepts of V and adjustable angled blades to offer route clearance and preparation options.